We Supply These & More

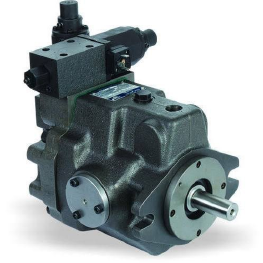

Hydraulics

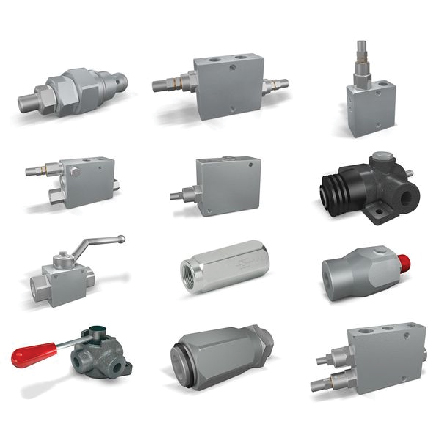

Valves

A hydraulic valve properly directs the flow of a liquid medium, usually oil, through your hydraulic system. The direction of the oil flow is determined by the position of a spool. A hydraulic system can only function - as per requirements - by using valves. Thus, you should always look for the correct type of hydraulic valve to serve your intended purpose. The required size is determined by the maximum flow of the hydraulic system through the valve and the maximum system pressure.

Hydraulics

Fittings & Adapters

Complete range of Adapters, the DIN 24 adaptors series of ISO 2353 8434-1/DIN, BSP adaptors series with a mechanical connection realized on a 60° conical seat, the fittings are made of steel (11SMPb37). The SAE J1453 ORFS adaptors are used in high pressure fluid-dynamics connections. JIC 37° ADAPTORS series is suggested for high pressure hydraulic connections (up to 350 bar) as it ensures a perfect seal system.

Hydraulics

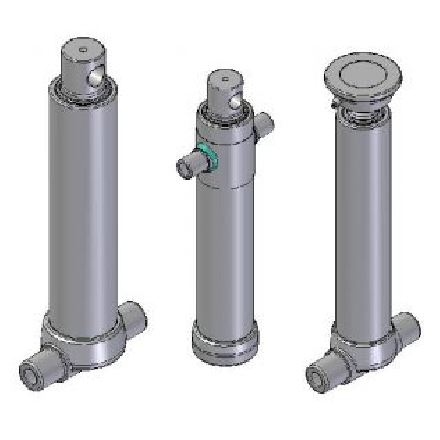

Cylinders

We supply a wide range of Hydraulic telescopic cylinders for various applications, a multi-stage rod built of a series of nested steel tubes of progressively smaller diameter. This special design of hydraulic cylinder provides exceptional travel from a highly compact retracted length. Typically the collapsed length of a telescopic cylinder is 20% to 40% of the fully extended length, depending on the number of stages.